foldAI

ID: 4251

May 20, 2022

Artificial sensing and intelligence for increased understanding and management of natural ecosystems.

ID: 3460

September 13, 2021

Aloxy is an Industrial IoT start-up founded in 2017 as a spin-off of the University of Antwerp and IMEC. The company has grown to 15 employees and has received funding of €3.2m. With a core market in petrol-chemical industry, Aloxy has a focus on valve maintenance and process safety. Their core product, the Aloxy Pulse, is a smart sensor device that is ATEX [1] and FCC [2] certified, allowing use in a range of industrial environments.

Aloxy’s core business offers solutions that improve risk management and reduces time spent on associated processes. For example, the process of manually operating and checking valves can often require two individuals to check valves at separate times to ensure security. The main users of Aloxy solutions are plant operators and technicians who integrate Aloxy systems with the plant’s operations, often with support from IT departments.

The incentive of Aloxy to develop an IoT solution was driven by a desire to optimise and streamline daily procedures in industrial contexts. This desire derived from an apparent lack of wireless technologies at operational level, which prevented monitoring of various important factors in the industrial work, with valve positions as a key factor. The solution led to the Aloxy Pulse, offering a low power sensor that can monitor control of valves, reducing the time needed to carry out manual tasks.

Having been the product of academic research at the University of Antwerp, the original seed came from a prototype badge holder that could be used for localisation of personnel in working environments and was presented at various conferences as a proof of concept.

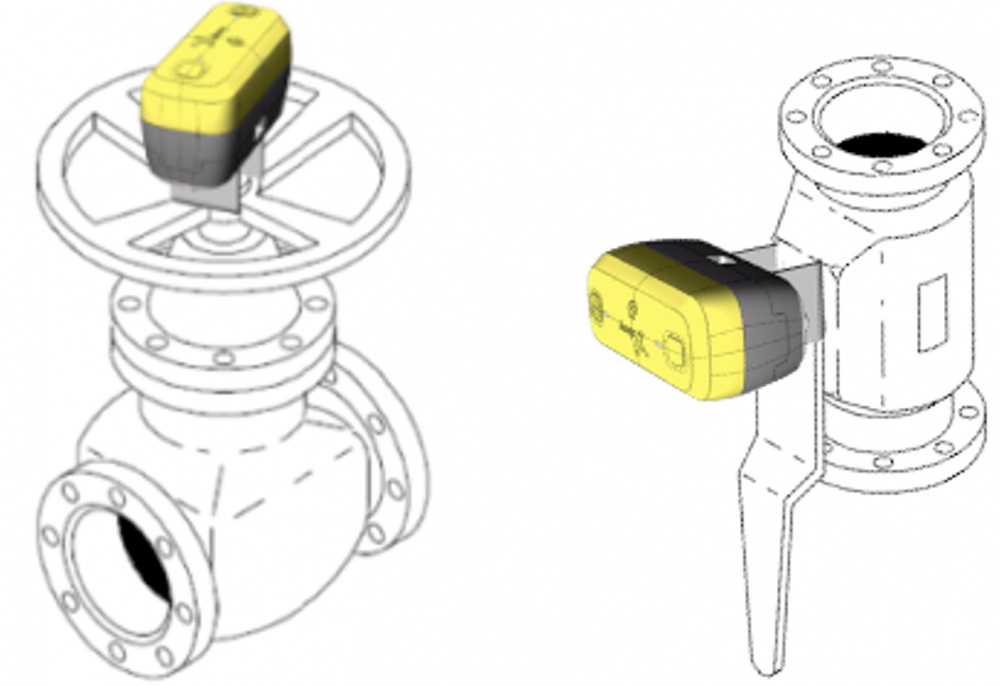

The driver of the final solution came through co-creation with industrial cases, resulting in a new product, the Aloxy Pulse, based on the same hardware as the badge holder prototype. The Aloxy Pulse is a specific and robust device that can provide a suitable quality of service, redundancy, effective energy impact, general cost and a suitable sampling mechanism for a wireless battery powered device. The characteristics of the Aloxy Pulse are considerably different to existing non-IoT valve monitoring solutions, and the connected capability opens a wide range of new and complementary applications.

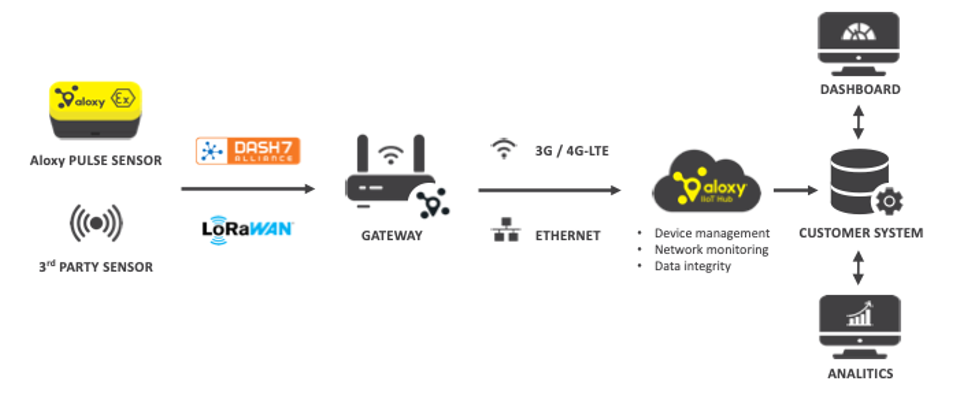

IoT is an essential enabler of the Aloxy Pulse technology, especially through connectivity options, including LoRa-WAN [3] and DASH7 [4], which are key innovations for the solution. Along with using low-power radio networks, a range of services were custom developed to ensure valid, reliable and well supported devices, which is crucial for proper data collection in networks where devices can lose connection, drop messages or lose power. These features include heuristics and flagging to account for issues that ensure false positives are avoided.

The users of Aloxy’s products are typically operators of petrol-chemical plants, as well as IT departments, with some interactions with plant owners.

“The basic service we deliver is the [valve status] data via our IoT hub to our client’s system.”

Maarten Weyn, Chief Research Officer at Aloxy

The Aloxy Pulse sensor is a battery powered device with a variety of sensors, including vibration, accelerator, rotational field, magnetic field, temperature and air pressure sensors contained in a small form-factor housing, which is ATEX approved, meaning it can be used in hazardous environments with protection from explosive atmospheres. The devices also include NFC [5] , buttons and LEDs for interactions with users. The device itself can be mounted to a variety of valves in different positions, fulfilling the same purpose to identify the open, closed or intermediate status of a valve. Further applications of vibration monitoring and geolocation are also offered.

The solution sports both LoRaWAN and DASH7 connectivity support LoRaWAN provides a 1 km connection range and suitable uplink to penetrate through industrial workspaces at a low power cost. The DASH7 protocol offers a sensor and actuator network with advanced features for secure over-the-air updates, higher data rates, direct and multicast communications that do not require a network server (unlike LoRaWAN), ensuring low latency, fast communication and removing a potential bottleneck. Aloxy contributes to the DASH7 Alliance open-source project by using the protocol as a key enabler of their products, being a member and proponent of the DASH7 community.

Aloxy’s end-to-end solution goes far beyond the sensor with the IIoT [6] hub, which is a software stack with optional connectivity choices and the possibility for customers to install on-premises software or cloud hosting. In most installations, the data that is transmitted and managed in the cloud is then integrated into customer systems for operators’ dashboards or other enterprise-based management software.

Aloxy offers the IIoT Hub for device management, network monitoring and data integrity, which is based on a variety of open-source products from the Eclipse IoT framework, including Digital Twin, Hono and Ditto. Aloxy also contributes to several open-source projects from Eclipse.

Aloxy automates several aspects of their internal system to ensure data integrity using device monitoring and various heuristic techniques [7]. Collectively these guarantee that false positives are reduced or prevented from reaching the customer.

“With IoT, if you’re using LPWAN technologies you can’t guarantee anything.”

Maarten Weyn, Chief Research Officer at Aloxy

Quality of service is critical, especially with LoRaWAN’s asynchronous communications needing both device and backend logic to confirm that what is being sent is accurate. This is solved with both edge and cloud-based algorithms providing accurate data to the customer, with a warning if there is a chance the alarm could be a false positive.

“The value is in the data processing itself.”

Maarten Weyn, Chief Research Officer at Aloxy

As the acquisition and delivery of accurate data is the main value proposition, Aloxy ensures data integrity across a range of data sets. Typically including event-based and time series data, this includes device alarms, valve position, trending (typically persisted by the customer), live data stream from Aloxy IIoT Hub and predictive models support efficient battery optimisations, which is particularly important for non-rechargeable battery devices.

Aloxy’s solutions have been well received by the petrochemical industry, with clients across Europe, the US and the Middle East (as well as interest from other regions, where the company have not yet focused on the certification yet in those areas), including BASF, Chevron and Total. The typical application has been to reduce man-hours spent on valve checks and in monitoring emergency equipment use.

As a company, value can be seen through company growth and continuous reporting on key metrics, such as hardware sales, recurring revenues, and number of proof-of-concepts carried out. Aloxy is also developing new products and devices that will open new industrial use cases.

Through the founding and growth of Aloxy, Weyn reflects on several challenges and realisations in creating an IIoT low-power product and recommendations that others may consider.

1. Focus on where your team is strongest

“The biggest mistake for some companies is trying to do everything yourself.”

Maarten Weyn, Chief Research Officer at Aloxy

On the use of open source, there are clear benefits from not reinventing the wheel, as well as pooling expertise and support amongst a network of other supporting companies, such as Bosch, as is the case with several Eclipse projects. Through using open-source technologies, all parties involved in the project are offered a level of assurances in knowing that if a start-up fails, the client may continue to use the hardware and take over the software operations or find a new IT partner.

This point, of using open source, was also relevant when seeking investors because investors do not want a team trying to build everything themselves, rather the effort must concentrate on the creation of new IP and technologies.

In contrast, some topics may need to be mastered by the company. Reflecting on the process of ATEX certification, Weyn considers that more in-house knowledge on certification procedures could have been valuable rather than relying on external experts that may have slowed the process.

2. Design for scalability

“You have to be naïve to start a company, we thought it [edge algorithms] would be an easy solution, but we still aimed at delivering a low power product.”

Maarten Weyn, Chief Research Officer at Aloxy

With several objectives of the Aloxy Pulse sensor, there is a fine balance between power management, data processing and radio usage to make a functioning data collection device. With this consideration, the range of functions are vast, however, to ensure a proper business solution, it must be scalable to many devices processing data efficiently and using network communications appropriately.

“We only want to design something, perhaps limiting features, that is scalable.”

Maarten Weyn, Chief Research Officer at Aloxy

With the need for scalability, it is also important that client systems can be integrated appropriately. Depending on the individual use case, the client company may have centralised or decentralised operations, with the first requiring much more management to create integrations and get projects started but can grow across a whole organisation, whilst the latter can get started much quicker, but each new plant will have to be approached differently.

“It takes much more time than just selling a product, there’s a whole integration with a client’s backend to consider.”

Maarten Weyn, Chief Research Officer at Aloxy

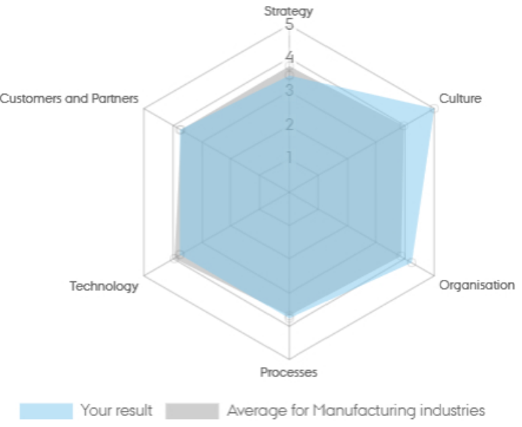

Aloxy assumes a high level of digital maturity with an overall score of 3.99. The highly ranked score may be explicated by the origination of the company as born digital. The score indicates that the digital capabilities of the company are vastly mature, and that they perform above average for the sector.

[1] ATEX (ATmosphere EXplosible): The ATEX directives are two EU directives describing the minimum safety requirements for workplaces and equipment used in explosive atmospheres

[2] FCC (Federal Communications Commission): Certification is the most rigorous approval process for RF Devices with the greatest potential to cause harmful interference to radio services

[3] LoRa: Long Range Wide Area Network

[4] DASH7: Alliance Protocol D7A is an open-source wireless sensor and actuator network protocol

[5] NFC (Near Field Communication): Standards-based short-range wireless connectivity technology.

[6] IIoT: Industrial Internet of Things

[7] Heuristic: technique designed for solving a problem more quickly when classic methods are too slow, or for finding an approximate solution when classic methods fail to find any exact solution. Often characterised by an approach to problem-solving that uses a practical method and various shortcuts.

Copyright notice: © 2020 – 2023 EU-IoT Consortium.

This material was produced as part of the EU-IoT project, grant ID 956671, and is funded by the Horizon 2020 Framework Programme under topic ID ICT-56-2020.

EU-IoT is the European IoT Hub. The EU-IoT project works towards growing a sustainable and comprehensive ecosystem for Next Generation Internet of Things.

Source of origin: Information to document this use case originates from a network collaboration w. the Eclipse Foundation and the LoRa Alliance (OSS community and not-for-profit associations); Case period: 2021-2022.